What is Silica Sand?

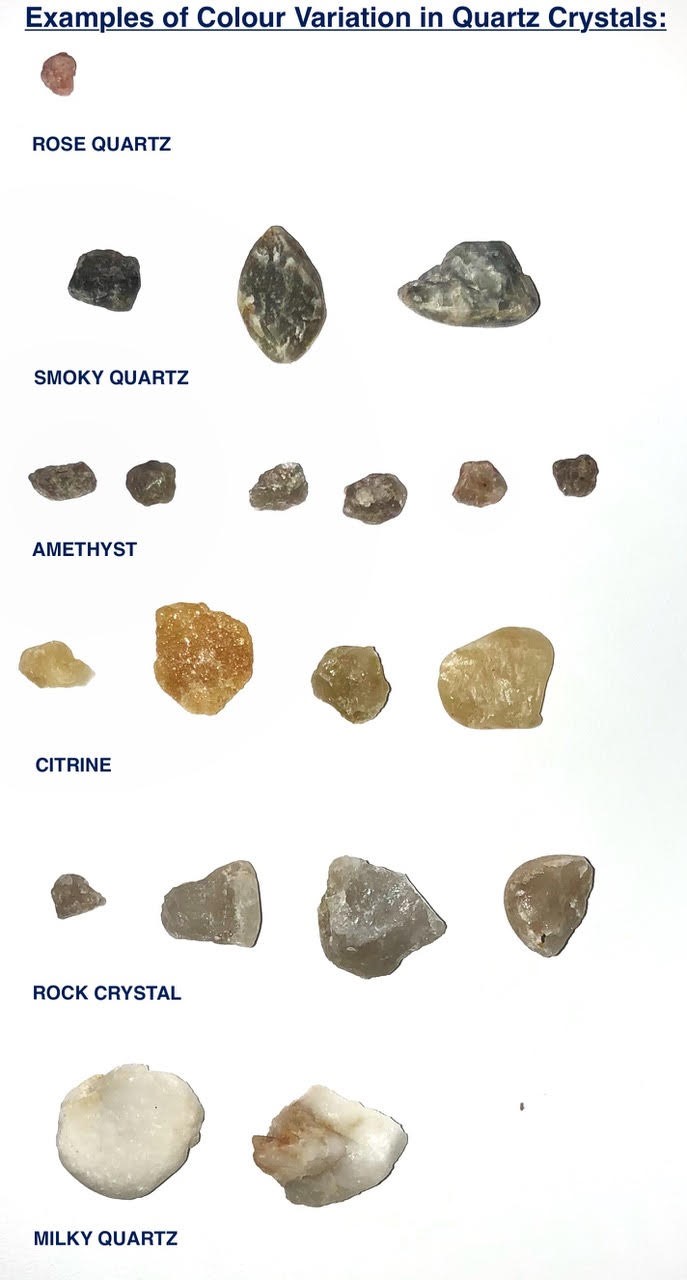

People often refer to Silica Sand as White sand, Industrial sand, or Quartz sand. It comprises two primary constituents: Silica and Oxygen, which combine to form silicon dioxide (SiO2). The quartz of silicon dioxide breaks down into tiny granules due to the effects of wind and water over time, resulting in Silica Sand. The composition of Silica Sand is typically 95% SiO2 and 0.6% Iron Oxide. The color of quartz crystals varies, such as Roze Quartz, Smoky Quartz, Amethyst, Citrine, Milky quartz, and Rock crystals, which depend mainly on the rock detritus and minerals.

How does Silica Sand differ from Regular sand?

Usually, concrete applications use regular sand that contains up to 80% of silica, along with other minerals like potassium, carbonate, and trace elements, resulting in various colors compared to silica sand. These impurities in non-silica sand give it a dull and irregular appearance.

It is used in a bunch of daily–life applications and some of them are listed below.

Silica Sand is a versatile element that finds application in various industries. Firstly, it is used as a mineral abrasive in industrial blasting, and care should be taken to follow proper PPE (Personal Protective Equipment) guidelines to avoid exposing oneself to dangerous dust. Secondly, golf courses and sports fields benefit from the ability of Silica Sand to maintain greens, fairways, and bunkers while supporting drainage and natural plant growth. Thirdly, Silica Sand is crucial in paints and coatings as it makes them durable, pigment-rich, and resistant to wear. Additionally, Silica plays a vital role in ceramics such as tiles, tableware, and other such products, and is considered the backbone of ceramic substances. Finally, it is also a raw material for standard glasses, further highlighting its nonpareil utility across multiple industries.

Mining Process

Silica is mined across the USA for more than a century. Sand mining started abundantly a few decades ago. There are two common methods for silica mining.

- Open Pit Mining

- Dredging Mining

Open-pit Mining also called open-cast mining, is a technique that extracts minerals from the open pit. Open-pit mining is the most uncomplicated method and doesn’t require any tunnels or extractive methods. This method is preferred when ore or deposit is found near the surface of the earth.

Different benefits of using this technique are:

- Low Cost

- Trouble-free drainage of subsurface water

- Low shut-down expense

- Mass production is easy

Dredging Mining refers to the underwater excavation of placer deposits through floating equipment. Thus depending upon the type of material transfer it is classified as mechanical or hydraulic.

Here are some benefits of Hydraulic dredging mining over mechanical excavation:

- Less Labor

- Less energy and emissions

- Less capital cost

- Less maintenance cost

During hydraulic dredging, the fines are washed from the sand while being transferred to the plant. Hydraulic dredging allows for direct transfer to the processing plants which reduces the re-handling of material.

For more information please contact us